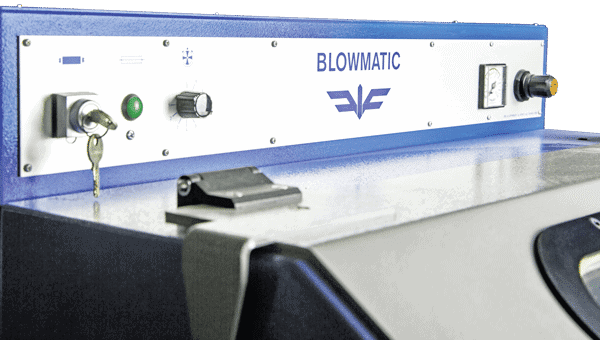

Blast cabinet BLOWMATIC

Technical cleanliness

in additive manufacturing

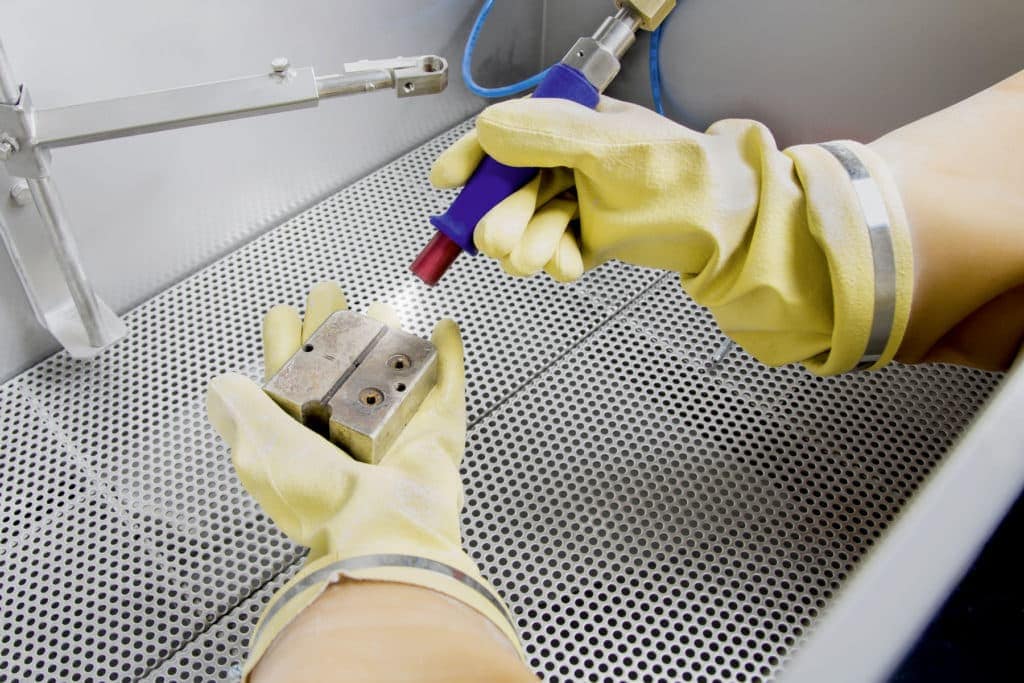

With the blast cabinet BLOWMATIC and COOLMASTER® an efficient, manual cleaning and deburring of small parts is possible. The user grasps the sensitive parts and the blasting nozzle of the COOLMASTER® via integrated arm cuffs and gloves.

Sealed off in the cabin, the parts are gently cleaned with dry ice without blasting agent residues or particle contamination. Cleaning and gentle removal of support materials.

Surfaces of sensitive components such as injection molds and 3D printing parts up to CNC milling, turning and grinding parts can be quickly cleaned and reworked.

Optimal for surface treatment of workpieces with dimensions of width 500 x depth 400 x height 250 mm.

Compact and space-saving on 2m² with the mobile COOLMASTER® the solution for technical cleanliness without surface damage in your production.

Technical Data:

| Electrical specifications | |

| Supply voltage | 230 V~ +PE, 50/60 Hz |

| Power consumption | 150W |

| Control safety | 4 AT |

| Compressed Air | |

| Connection supply | 1/2" G |

| Connection equipment | 1/4" G |

| Operating pressure/Supply pressure | 0,5 - 10 bar |

| Noise emission output | |

| Without microblasting | 58 dB(A) |

| With microblasting at 3 bar | 65 dB(A) |

| Sizes and weight | |

| Width | 740 mm |

| Depth | 520 mm |

| Height | 500 mm |

| Weight | 205 kg |

Basic equipment:

- Front flap door supported by gas-pressure cylinders can be opened up to the working height of the micro blasting equipment, with integrated inspection window with a safety and an attrition-proof glass (double glass) in a quick change frame

- Cabin lighting

- Manual, hydraulic adjustment of height (maintenance-free)

- 2-feet system with built-in rollers, moveable, can be locked manually

- Working grate made of perforated plate, two-piece, detachable, diameter of holes 5 mm

- Padded sleeves and gloves, exchangeable

- Holding device for microblasting gun with swinging arm for COOLMASTER® nozzles height 115 mm, swiveling range 275 mm

- Ventilator for high surface microfilter unit, electronically continuously variable

- Foot actuated switch with impulse contact

- Compressed-air connection, 1/4” G, at equipment, including oil and water separator

- Control panel with all necessary switches and control elements

- Key-operated switch, on / off, with 2 keys

Hose package for COOLMASTER® with foot switch: