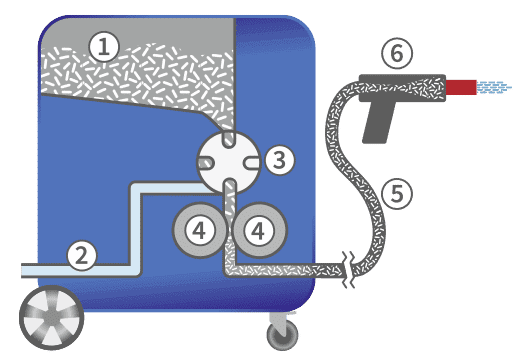

Our grinder system is integrated into the machine. This special construction makes the COOLMASTER® unique.

In contrast to conventional dry ice blasting machines, which often first grind the dry ice pellets in the gun, the grinding mechanism of the COOLMASTER® is already placed inside the machine before the blasting process. This is where the dry ice pellets are grinded into a consistent size.

This special construction results in considerably lower air supply requirements than other dry ice blasting machines.

An additional advantage of this construction is that the blasting gun is light and easy to handle, which makes daily use and especially longer cleaning tasks more comfortable.

The grinding mill – Right in the middle:

-

Hopper with pellets

-

Compressed air

-

Rotating dosing roller

-

Grinding rollers

-

Blasting hose

-

Blasting gun with laval nozzle

The advantages:

-

No blockage of the unit or grinding system due to technical reasons

-

Homogeneous and consistent cleaning jet

-

Precise dosage of compressed air and amount of dry ice

-

Grinding size of the pellets between 0,2 and 3 mm

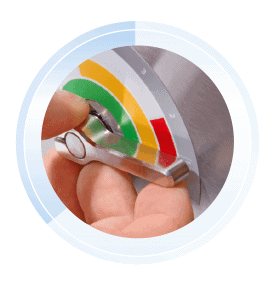

Intuitive operation – so easy:

1. Grinder adjustment

You set the grinding degree according to your cleaning task and surface structure. The COOLMASTER® grinds dry ice particles flexibly from 0.2 – 3 mm.

You can change and adjust the size of the dry ice particles at any time.

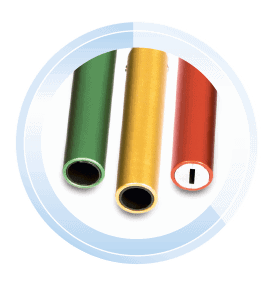

2. Selecting the blasting nozzle

When the particle size has been set, simply screw the matching blasting nozzle onto the blasting gun.

The nozzles can be easily changed under all operating conditions.

3. Program setting

The adjustment of the compressed air is essential for an effective and precise cleaning. Therefore the compressed air jet is continuously adjustable from 0.5 to 10 bar (7 to 144 psi).

Standard values are already stored in the programs. In addition, you can set and save frequently used values individually.

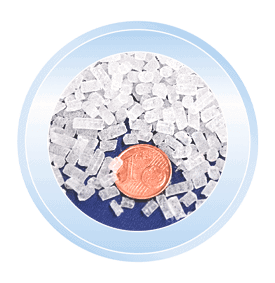

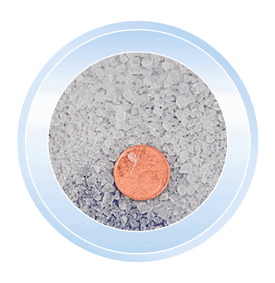

Examples of particle sizes:

Particle size COARSE

Particle size MEDIUM

Particle size FINE